VITHY® VVTF Precision Microporous Filter adopts sintered PE (PA/PTFE/304/316L/titanium) filter tube as the filter medium. Its pores are thin and curved, which can filter solid particles above 0.1 microns, and the filtrate is clear. When filtering particles below 0.1 microns, only few particles will go through the filter tube at startup. Once a thin filter cake layer has formed, the filtrate becomes clear quickly.

The microporous tube is a kind of microporous piece with much better rigidity than foam and plastic. When the temperature is not too high (304/316L can withstand high temperature), it has little deformation under the action of tension and pressure. The filter cake formed on the outer surface of the filter tube is easily detached as long as it is back-blown with compressed air. Even viscous cake can be detached as long as the compressed air pressure is high and the intake speed is fast. However, for viscous filter cakes, if the filter medium is a filter cloth, it is difficult to detach the cake with the current common self-weight cake detachment, vibration cake detachment, or back-blowing cake detachment, unless the method that back-blow the cake into the bottom residual liquid is adopted. Therefore, the microporous tube can solve the problem of the detachment of the viscous filter cake. The operation is simple, and the mechanical equipment structure is compact and uncomplicated. In addition, after the filter cake is detached by back-blowing compressed air, the air is shot out of the pores at high speed, and the kinetic energy of the airflow can force the solid particles blocked in the pores during filtration to discharge. As a result, the cake detachment of the microporous filter and the regeneration of the filter tube is convenient, and the labor intensity of the operators is low.

The microporous filter made of PE/PA/PTFE has excellent chemical properties. It can resist acid, alkali, aldehyde, aliphatic hydrocarbons, radioactive radiation, etc. It can also resist ester ketones, ethers, and other organic solvents below 80 °C (PA 110°C, PTFE 160°C). The microporous filter made of 304, 316L can withstand high temperature, up to 600 °C.

The filter is suitable for precision liquid filtration with a large solids content and high requirements for the dryness of the filter residue. The microporous PE/PA/PTFE/304/316L/titanium filter tube with superior chemical properties can be back-flown or back-flushed many times, greatly reducing the cost of use.

■ No residue: Filtrate and liquid residue are jointly recovered.

■ Completely sealed filtration, clean production, no environmental pollution

■ It has been widely applied in precision solid-liquid filtration (e.g., activated carbon decolorization liquid, catalyst, ultrafine crystal, etc.) that has a large amount of filter cake and high dryness requirements in fine chemical, biopharmaceutical, food and beverage, petrochemical and other industries.

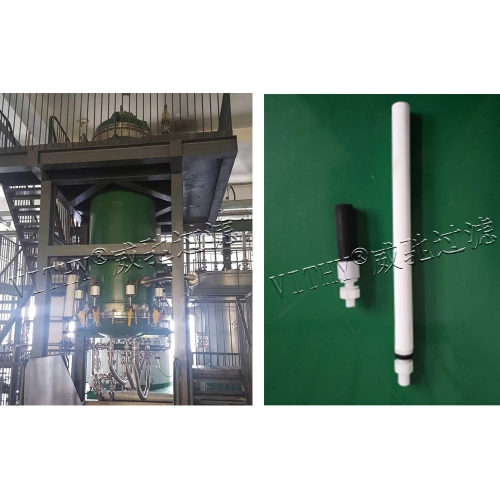

PE/PA/PTFE Microporous Filter Tube

The filter tube made of sintered ultra-high molecular weight polyethylene powder is the core filter element of the microporous filter.

■ Filtration precision up to 0.1 microns

■ High back-blow/back-flush efficiency, long service life, and low cost

■ Superior chemical corrosion resistance: Resistance to most solvents below 90 °C; odorless, non-toxic, no peculiar smell dissolution

■ PE temperature resistance≤90 °C, PA temperature resistance≤110, PTFE temperature resistance≤200℃,304/316L temperature resistance≤600℃

Applicable Industries and Fluids

■ Filtration and washing of ultrafine products (such as catalysts, molecular sieves, ultrafine magnetic particles, etc.).

■ Precision filtration and washing of biological fermentation broth

■ The fermentation, filtration, and extraction of the first filtration; the precision refiltration to remove precipitated proteins

■ Powdered activated carbon precision filtration

■ Precision filtration of medium and high temperature oil products in the petrochemical industry

■ Precision filtration of primary or secondary brine in chlor-alkali and soda ash production

Main Technical Parameters

Main Performance Parameters | VVTF-5 | VVTF-10 | VVTF-20 | VVTF-30 | VVTF-40 | VVTF-60 | VVTF-80 | VVTF-100 |

Filtration Area (m²) | 5 | 10 | 20 | 30 | 40 | 60 | 80 | 100 |

Filtration Precision (μm) | 0.1-100 |

Filter Element Material | HMW-PE/PA/PTFE/304/316L/Titanium powder sintered filter element |

Maximum Operating Temperature (℃) | ≤200 (304/316L—600℃) |

Operating Pressure (MPa) | ≤0.4 |

Housing Material | 304/304L/316L/ carbon steel /PP lining/ fluorine lining/904/titanium material, other materials can be customized (e.g. dual-phase steel, etc.) |

Control System | Siemens PLC |

Automation Instrumentation | Pressure transmitters, level sensor, flowmeter, etc. |

Back-blowing Pressure | 0.4MPa~0.6MPa |

Note: The flow rate is affected by the viscosity, temperature, filtration precision, and particle content of the liquid. For details, please contact VITHY® engineers. |

No. | Filtration Area

(m2) | Theoretical Flow

Rate (m³/h)

| Filter Housing Volume (L)

| Inlet/Outlet Diameter

(DN) | Sewage Outlet Diameter

(DN) | Filter Housing Diameter

(mm) | Total Height

(mm)

| Filter Housing Height

(mm)

| Sewage Outlet Height

(mm)

|

1 | 1 | 1 | 40 | 20 | 100 | 300 | 1400 | 1000 | 400 |

2 | 2 | 2 | 76 | 25 | 100 | 350 | 1650 | 1250 | 400 |

3 | 4 | 4 | 175 | 32 | 150 | 450 | 2100 | 1600 | 500 |

4 | 5 | 5 | 200 | 40 | 150 | 500 | 2150 | 1650 | 500 |

5 | 15 | 15 | 580 | 50 | 250 | 800 | 2300 | 1700 | 600 |

6 | 20 | 20 | 900 | 80 | 300 | 1000 | 2500 | 1800 | 700 |

7 | 50 | 50 | 1800 | 100 | 350 | 1200 | 3200 | 2400 | 800 |

8 | 65 | 65 | 2600 | 150 | 350 | 1400 | 3300 | 2500 | 800 |

9 | 80 | 80 | 3400 | 150 | 400 | 1600 | 3380 | 2580 | 800 |

10 | 100 | 100 | 4500 | 150 | 450 | 1800 | 3450 | 2650 | 800 |

11 | 150 | 150 | 6000 | 200 | 500 | 2000 | 3600 | 2800 | 800 |